Channel Furnace Aftermarket and Inductor Repairs

Our advanced facility and top level mechanics ensure that Inductotherm can continue to provide customers with high-quality induction channel furnace parts and inductor remanufacturing.

The Benefits of OEM Parts, Repairs, Service and Support

If you are in the market for aftermarket, talk to us first. Inductotherm is well-known for advanced melting, heating, holding and pouring equipment. Did you also know that as the Original Equipment Manufacturer (OEM), we provide our customers with proper aftermarket care and parts? Only Inductotherm Corp. can ensure your repair is done to OEM standards in our ISO-certified shop in Rancocas, NJ. Expert advice, knowledgeable staff and cost-effective solutions are simply a call away.

As the Original Equipment Manufacturer (OEM), we:

- completely disassemble inductor and strip all the old insulation off the inductor coil and sandblast the coil to bare copper to identify any problem areas.

- know what coil insulation is required for your application.

- can offer new/available upgrades to enhance safety, performance and reliability.

- remanufacture the inductor by bringing it back to today’s standards.

Inductotherm OEM coils that are remanufactured go through unmatched and stringent testing, including a helium leak test. While helium is an extra expense, it is proven to be the best way to accurately check for even the smallest coil leak since helium molecules are smaller than water. Avoiding these problems is crucial to minimize costly downtime and delays. That’s why using the most advanced technology on the market today to prevent these situations is key. You can be assured that Inductotherm can bring your inductor coil back to today’s standards. Proper coil insulation and the technical expertise required to properly apply it is critical, as the wrong insulation, mechanical design and support material could lead to shorter coil life, early coil failure and costly downtime.

Keep Your System Running at Peak Performance with the Proper Tools and Spare OEM Parts

Replacement Parts and Maximum Customer Up-time Go Hand-in-Hand

Maintain your melting or holding system’s high level of quality, reliability, safety and performance by using only recommended and authorized Original Equipment Manufacturer (OEM) replacement parts purchased from Inductotherm Corp. Using substitute or unauthorized parts can cause equipment malfunction, resulting in equipment or property damage, including injury to personnel. Never accept third-party imitations for you induction channel furnace and inductor parts.

Our equipment is designed and built to withstand the most demanding conditions. Yet if anything should happen, immediate response, extensive technical knowledge, in-depth experience, readily available parts and a company-wide dedication to customer satisfaction are the hallmarks of our unparalleled customer service and support. If technical support, service or parts are needed, we maintain a substantial inventory of OEM spare parts and have created a highly mobile worldwide multinational service team available around the clock to ensure maximum up-time at each customer’s facility.

Each Inductotherm channel induction furnace and inductor is shipped with a “Recommended Spare Parts” List. That list is unique to your system. It includes a list of detailed parts customized to your specific unit. To prevent unnecessary downtime, we recommend that each customer stock the items listed under recommended spares for your channel furnace and inductor. However should you be caught off guard, we continue to maintain our large inventory of readily available parts that can be shipped out immediately.

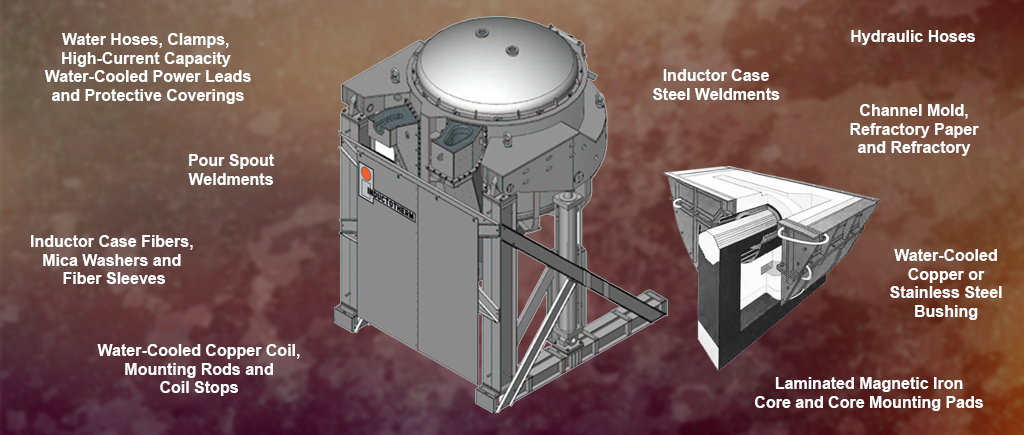

Parts commonly found on a “Recommended Spare Parts” List include:

| Inductor Coil |

| Coil Mounting Insulation |

| Inductor Core |

| Core Mounting Insulation |

| Inductor Case |

| Inductor Case Insulation |

| Channel Mold |

| Inductor Refractory Paper |

| Hydraulic Cylinder, Hose and Seal Kits |

| Pivot Bearings |

| Power Leads |

| High Resistance Water Hoses and All Stainless-Steel Hose Clamps |

| Protective Fiberglass and High Temperature Silicone-coated Sleeves for Water Hoses and Power Leads |

| Water Temperature, Pressure, Flow Gauges and Switches |

Inductotherm Channel Furnace High Current Capacity Leads Provide Lower Power Losses

When you choose Inductotherm you can be sure you are getting the right leads for your Inductotherm melting or holding system. We make the highest quality, high-current capacity leads for any application where flexible leads are required for carrying currents in frequencies from 60 to 10,000 hertz. With over 65 years of experience, you can trust that these leads were designed with efficiency in mind. Our water-cooled flexible leads provide maximum service life, lower power losses and reduced maintenance costs on any application where flexible leads are required. We use a flexible copper cable enclosed within a high grade rubber hose and fitted with a flare type terminal fitting that facilitates making both water and electrical connections easier.

Don’t forget to inquire about our trade-in program which offers a discount when you trade in your old leads.

As your OEM, we can assess your needs and supply guaranteed solutions. Other benefits include:

- Our non-conductive hose provides longer life and is less likely to kink

- We take the guess work out by calculating the correct hose size needed, ensuring proper water flow

- By determining the proper number of copper cables necessary, you achieve the highest efficiency