Horizontal Induction Tunnel Furnace Systems

Horizontal induction tunnel furnaces produce higher quality gold and silver bars.

Gold and silver bars must be of good appearance and meet the precious metals industry high standards. This is one of the reasons why Inductotherm created a newer method that has been proven to allow for many small cast bars to be manufactured at the same time. The gold/silver granules and small cut pieces are placed in a bar mold of the required size. Several molds that are grouped together are then fed into an induction furnace for melting at a controlled temperature. When the gold/silver has melted, the molds are then pushed gradually through a cooling tunnel via an automated system with a digital display. Solidification and subsequent cooling occur in a protective atmosphere. When the molds exit the tunnel, the small cast bars with shining surfaces are removed.

How It Works

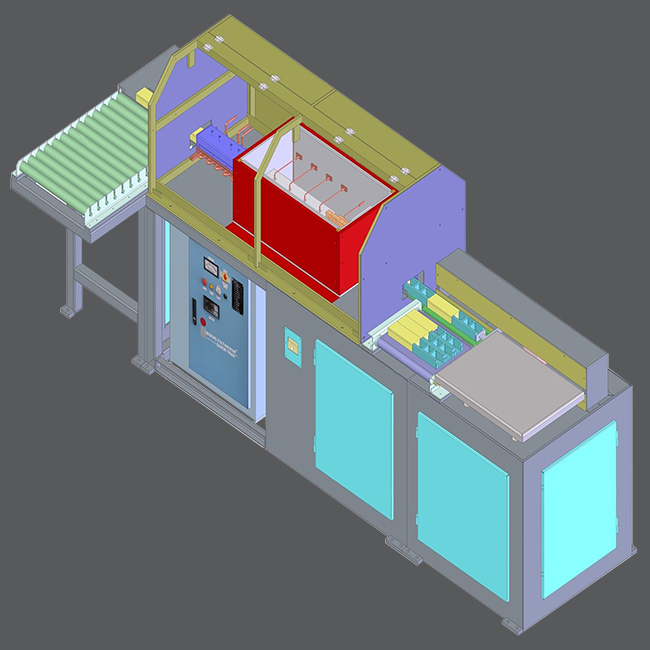

A fully automated induction tunnel furnace takes the form of a sealed tunnel-like enclosure that is composed of three distinct inner chambers. The entire tunnel is sealed, right from the entry to the exit, which contains the inert gas atmosphere. This is crucial to the ingot mold life as it eliminates oxidation. The mold containing gold or silver is driven by an automated pusher, moving the mold into the melting chamber, then into the solidification chamber for treatment based on the metallurgical properties, which produces a glossy mirror finish ingot.

Next, the mold moves into the cooling chamber which produces good quality bars due to the absence of oxidation. The mold then passes through the sealed exit chamber to a conveyor. The first step is to place the exact amount of gold or silver in a bar mold of the desired size. Several molds, all grouped together, are then fed into an induction furnace for melting at a controlled temperature.

When the gold or silver has melted, the molds are then pushed gradually through a cooling tunnel. When the molds exit the tunnel, the bars are removed, cleaned and weighed. As in the traditional process, any excess gold or silver is removed through filing, normally using a linisher machine. Excess gold or silver is usually taken from one of the corners of the bar. Approved bars are marked, as required, with the designated weight, purity, official stamp/certification mark and serial number.

Article

Article