Investment Casting

Maximum Efficiency for Investment Casters

Induction melting is widely used in investment casting applications. We offer a wide variety of air and vacuum induction melting (VIM) furnaces that are ideal for the investment casting of virtually all metals.

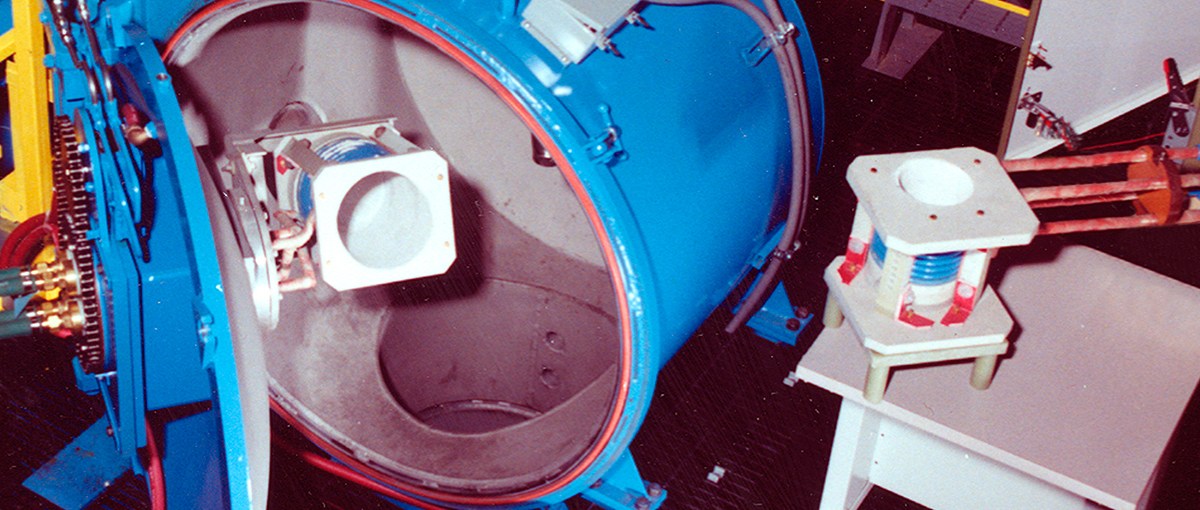

Specialty furnaces, like our rollover furnace, are specifically offered to this market for nonferrous and ferrous alloy castings ranging from medical implants to precision castings for aerospace applications.

Our Vacuum Induction Melting Furnaces are used to create high-quality castings that are not feasibly produced in an air atmosphere.

Coreless induction furnaces have proven to be a valuable tool for reliably producing molten metal that is homogeneous and uniform in temperature for the investment casting industry.

Selection of Furnace Size, Power Rating and Frequency:

- Capacity of the furnace is determined by the weight of your pour.

- Must select the optimum power rating for your system.

- Primary factors in selecting equipment is metal quality, and melt rate.

There are a wide variety of gravity pouring furnaces that range from our small hand-poured Mini-Melt® Furnaces which are widely used in the investment casing industry–while our larger Double-Trunnion Dura-Line® Furnaces are designed to allow precise pouring directly into molds, eliminating the use of a transfer ladle and mold handling during the pouring process.

Our VIP® Multi-Output™ Power Supply Units are able to run several furnaces simultaneously using two or more individually controlled power outputs, increasing metal production at the same power rate as a single-output system.

Inductotherm also provides Graphite Heating Systems for Directional Solidification & Single-Crystal casting process. Our single-zone heating coils with a VIP® Power-Trak unit as well as our multi-zone heating coils with our VIP® Dual-Switch & VIP® Multi-Switch™ units are widely used in the aerospace industry.

Inductotherm’s advanced melt shop automation provides the investment casting industry with the competitive edge to repeatedly produce castings with high dimensional accuracy and intricate design, while at the same time optimizing power usage, automating many functions, and improving operational safety. Our technologically advanced equipment is designed to reduce costs, and improve the quality, efficiency, and safety of the induction melting process. We offer melt system controls in various levels of features and capabilities that can help investment casters enhance their melt shop operation.

Why Inductotherm?

As the world’s leading manufacturer of induction metal melting systems for metal producers today, Inductotherm has built more than 38,500 melting and heating systems for metal and metalcasting producers around the globe.

Inductotherm offers our clients the industry’s highest level of expertise, support, and services. Contact us anytime.

Rollover Furnaces are ideal for close control of pouring and metal quality to produce high-end investment castings.

Inductotherm Vacuum Induction Melting (VIM) Furnaces are designed specifically for operation in high vacuum environments and include vacuum-adapted construction methods and the industry’s most advanced coil and connector dielectric insulation technologies and procedures.