TILT-POUR™ Furnaces

TILT-POUR™ Furnaces provide flexibility in both production needs and alloy requirements.

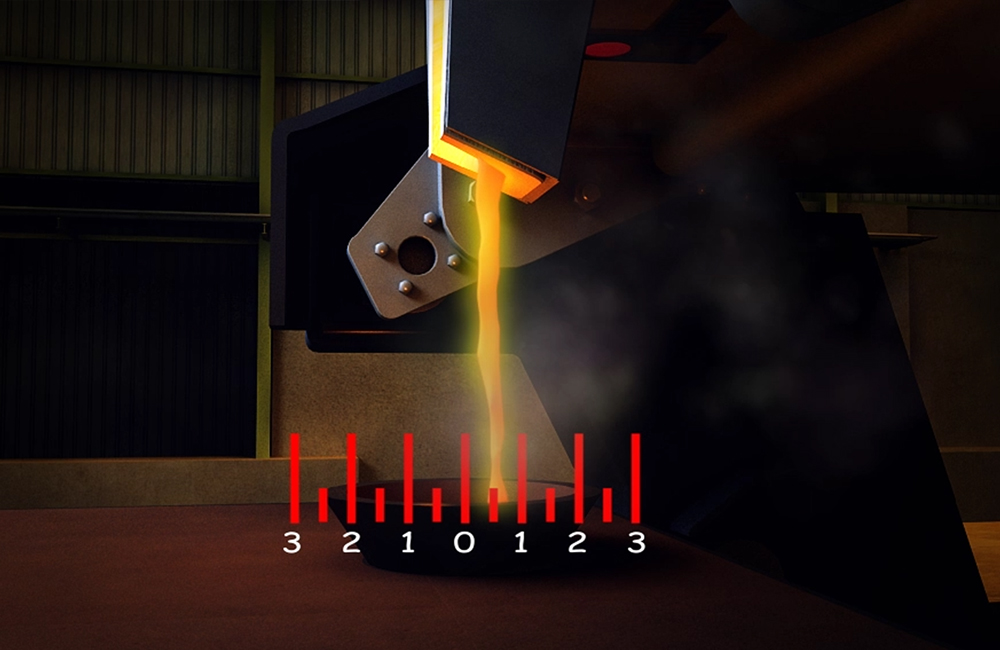

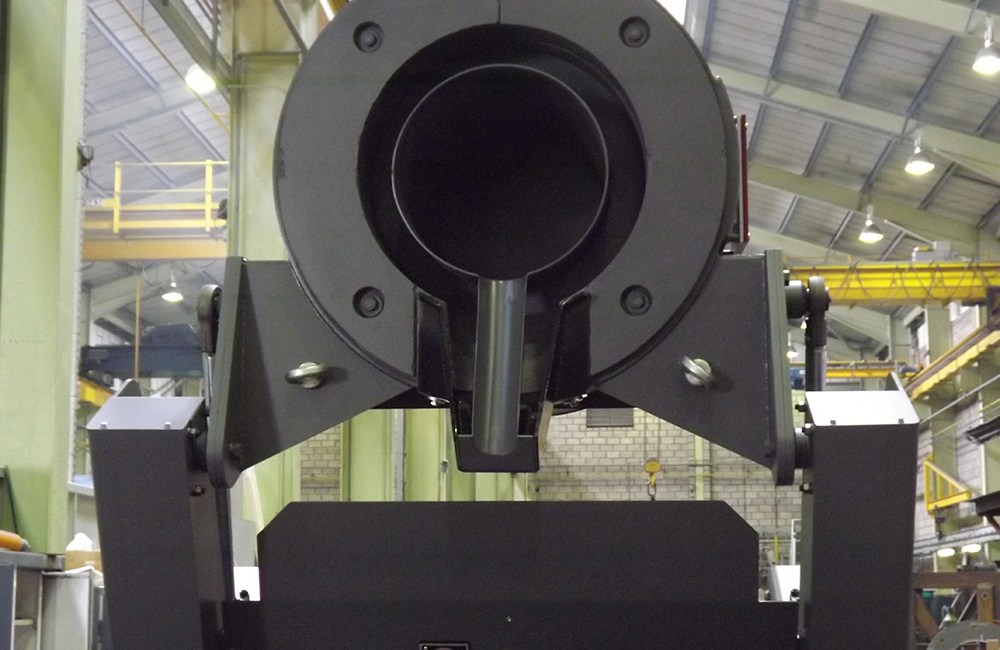

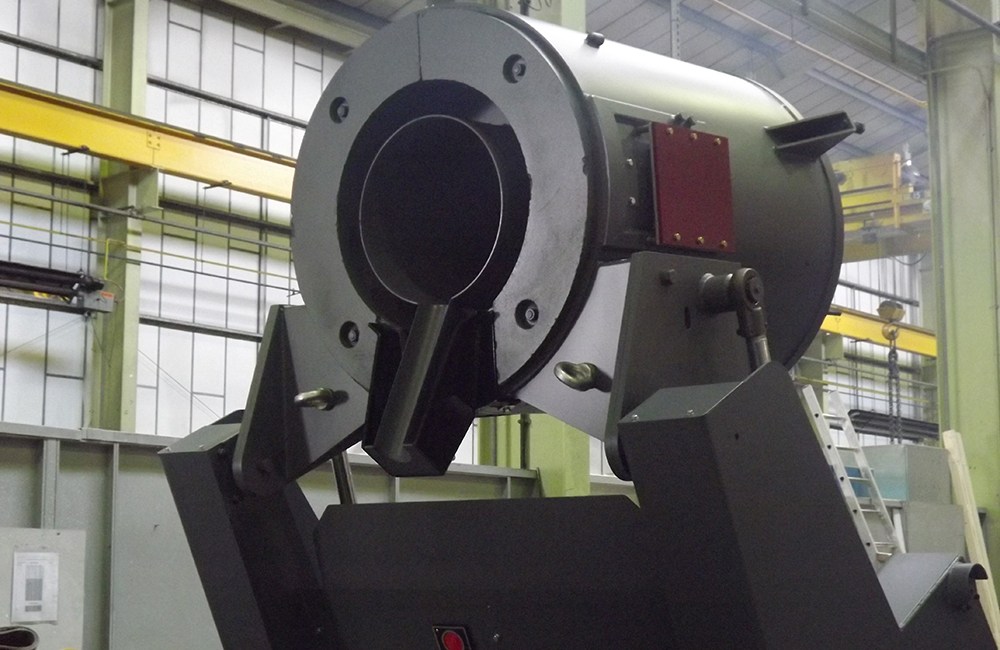

TILT-POUR™ Automated Pouring Furnaces utilize an induction furnace for the dual roles of melting and automated pouring. They feature a coreless induction furnace which melts a specified quantity of metal and delivers temperature control in close proximity to the point of pouring. Finely-tuned furnace tilting control is paramount for accurate metal dispensing into the mold cavity. For this, the coreless furnace is outfitted with a clever arrangement which not only offers exceptional control, but maintains the pouring stream on the same line of trajectory throughout the tapping/pouring cycle. Special adaptive software tracks and corrects the tilt angle precisely for physical differences within the furnace lining system. This concept is especially well suited for shell and investment molding in steel cast shops. To maintain even higher levels of production, melt shops use VIP® Multi-Output™ Power Supply Units which allow for multiple furnace configurations whereby one furnace can be melting while another is at the line pouring.

Features

| Standard Features | Optional Features |

|---|---|

| Tilt Pouring Control While Maintaining Metal Trajectory | Accurate Tilt Pouring Control |

| Hydraulic Tilting | X-Y Axes Motion |

| Insulated Cover |

Tech Specs

| Capacities | Factory Tested |

|---|---|

| 250 to 1,500 Kilograms [550 to 3,300 Pounds] | Critical Components |

| Click here to contact Inductotherm for Custom Solutions |

Control Options

TILT-POUR™ Furnaces use a precise, closed loop hydraulically-driven control to accurately dispense metal directly from the coreless melting/holding furnace. Special adaptive, intelligent software combined with metal weight, furnace positional information and liquid levels deliver metal in the exact quantity and at the proper flow rate necessitated by the mold.

Literature

Literature