High Resistance Load (HRL) Melting Systems

Melting with induction in vacuum or inert gas atmosphere require furnaces and power supply units designed for these demanding environments. Inductotherm has developed a line of solid-state power supply units specifically tailored to the demands of High Resistance Load (HRL) Melting Systems.

How It Works

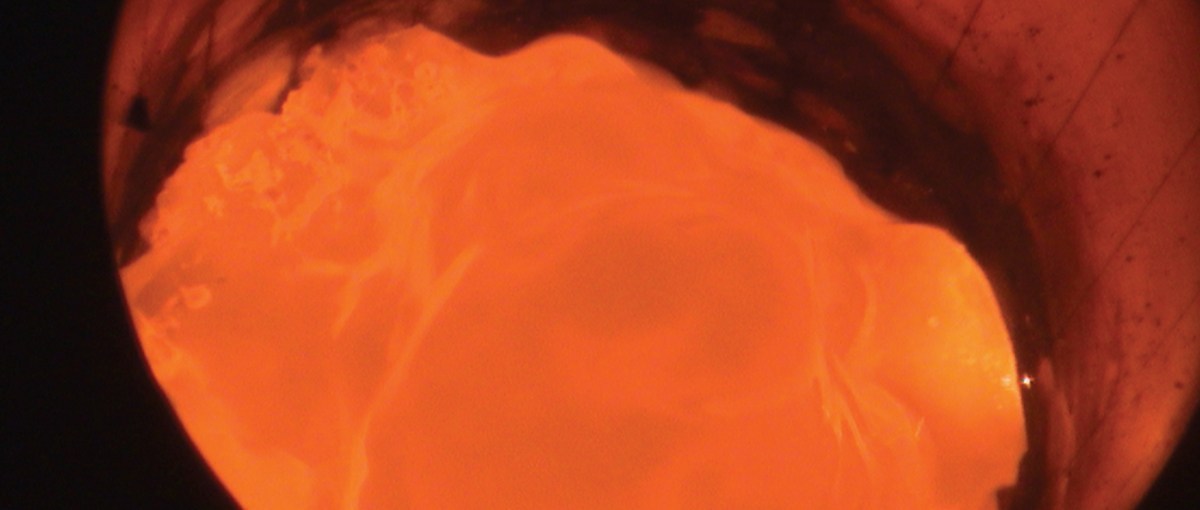

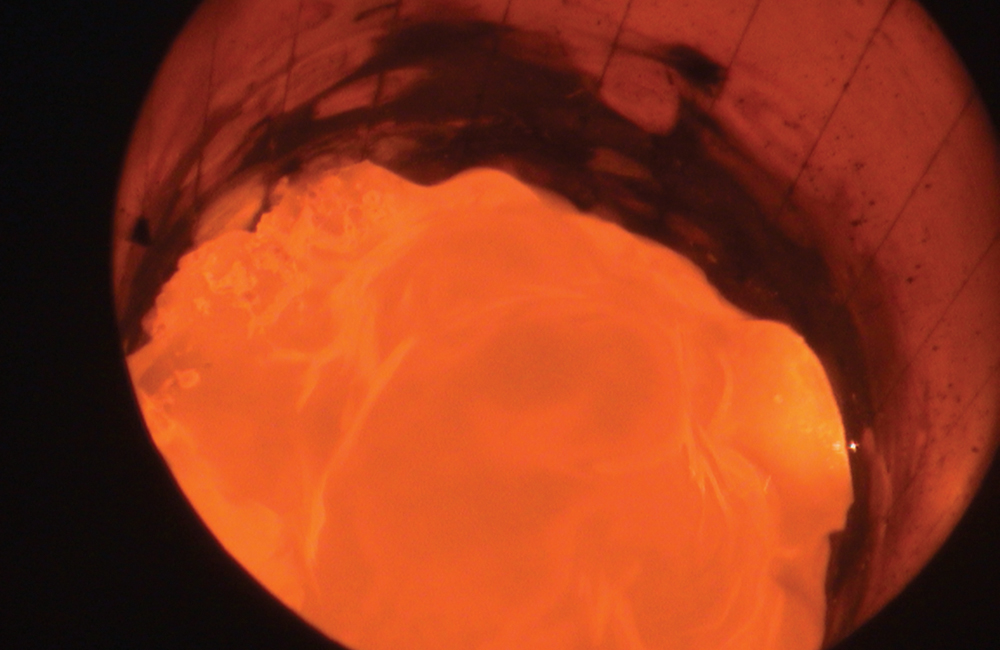

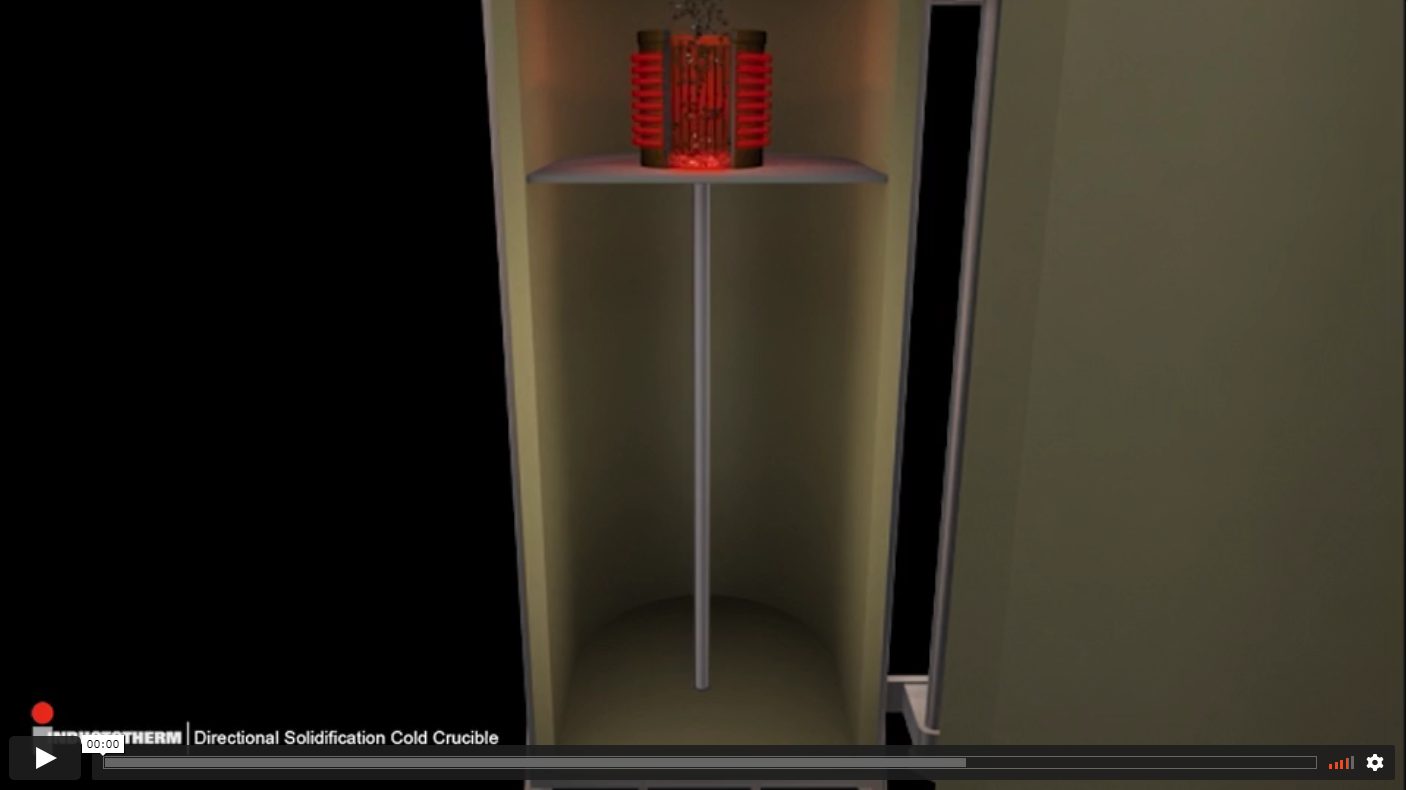

High Resistance Load (HRL) Melting Systems use our VIP® Power Supply Units that have been updated and refined over the years. High temperature metals such as titanium and titanium alloys cannot be melted in regular crucibles since in a molten state, they react with refractory metals. Therefore they are melted in a slotted water-cooled copper crucible. A high-density magnetic field not only heats the metal, but also squeezes it away from cold crucible walls, minimizing heat transfer. Higher output frequencies ensure proper metal stirring levels and more rugged componentry due to the much higher current levels at which these units will run.

Features

| Standard Features | Optional Features |

|---|---|

| Cup Feeder | Economical Single Chamber Systems |

| HRL Crucible | Multi-Chamber Systems |

| HRL Mold | Centrifugal Caster |

Tech Specs

| Capacities | Factory Tested |

|---|---|

| Click here to contact Inductotherm for Custom Solutions | Critical Components |

Literature

Literature

Article

Article