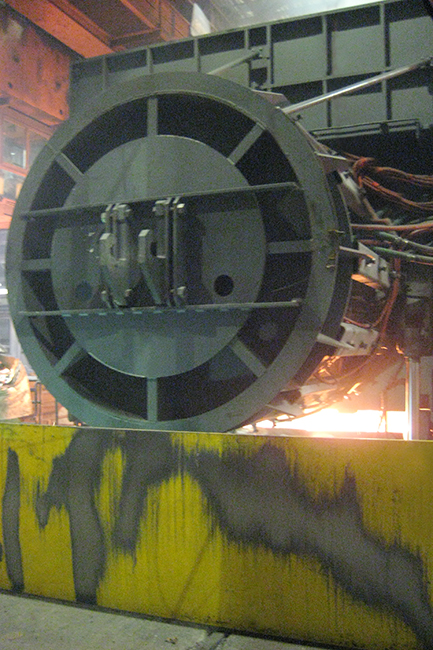

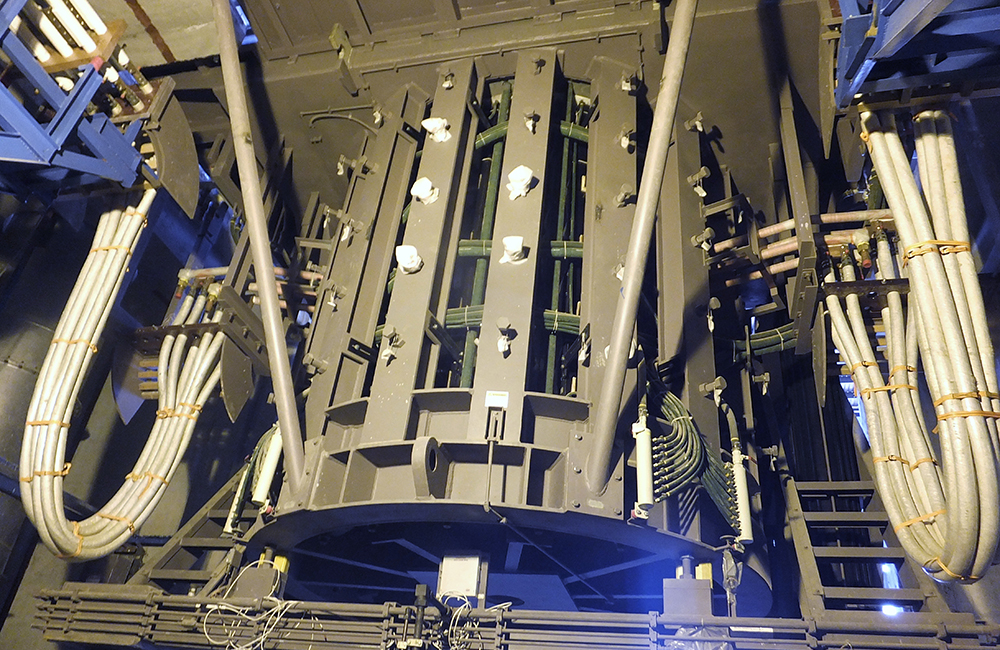

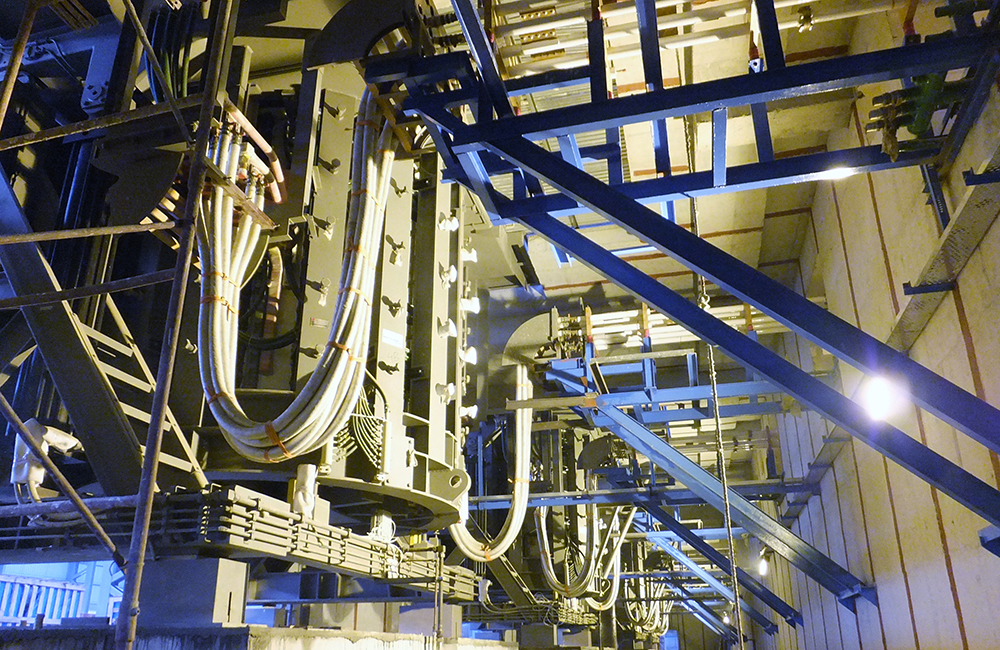

Steel Frame Furnaces

Steel Frame Furnaces combine the strength of a rugged steel frame with the easy accessibility of a frame furnace.

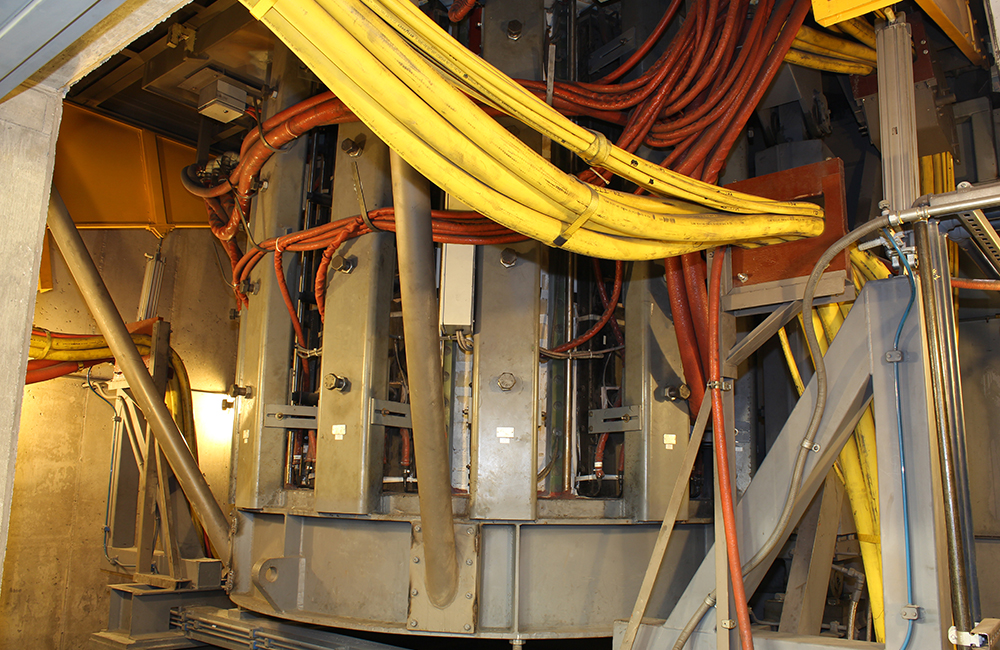

Due to our superior design and technological expertise, Inductotherm Steel Frame Furnaces are more efficient and easier to maintain than competitive furnaces. Steel Frame Furnaces feature rugged construction to minimize distortion during tilting and pouring operations. They are designed with a high freeboard and provide extra space for solid charge materials, enabling its cover (optional) to be easily closed as the charge melts, greatly reducing heat loss. The raised hearth (optional) provides a convenient fulcrum for easy slag and dross removal and also acts as a safety barrier for your workers, helping to shield them from excessive heat when the cover is off. The thick-walled tubing in Steel Frame Furnaces has a larger current-carrying cross section than comparably sized tubing so it offers lower resistance. This allows more energy to go into the melt. Every Steel Frame Furnace is designed for its structural strength with the help of specially developed computer-aided software.

Features

| Standard Features | Optional Features |

|---|---|

| High Freeboard | Push-Out Lining System |

| Heavy Tubing | Load Cells |

| Magnetic Shunts | Back-Tilting Systems |

Tech Specs

| Capacities | Factory Tested |

|---|---|

| 4 to 60 Metric Ton [4.5 to 66 Short Tons] | Critical Components |

| Click here to contact Inductotherm for Custom Solutions |

Safety Options

Safety Options and Retrofits are critical for guarding your equipment against possible failures. To improve each units overall efficiency and safety, Inductotherm provides options that can be retrofitted as needed to provide you with the most advanced equipment without replacing entire units, which include:

- Close capture furnace fume covers assist our customers with MACT compliance. We offer a full range of covers that can be retrofitted to almost all large and small Inductotherm coreless induction furnaces, new and existing. These covers are designed to effectively collect smoke, dust and airborne pollutants during all phases of furnace operation. The Vortex™ extraction hood is a high velocity hood that offers many benefits including less escaped fumes and better access.

- Lining Push-Out Systems for furnaces greatly reduce the time and labor for refractory lining changes by using a large movable plug to push out the entire lining in just minutes for easy disposal. It reduces exposure of foundry personnel to refractory dust which improves working conditions along with profitability and productivity.

- Back slagging permits the furnace to tilt at a 33 degree angle toward the rear. Tilting the furnace provides sufficient space above the deck for a portable hopper which will make it easy for the slag to be pulled through the rear spout into the hopper.

- Back tilting is offered where approximately 12 degree back tilt angle is achieved for slag removal, utilizing a lower cost tilt frame with extended cylinder construction. Nose tilting shifts the furnace rotation point forward, increasing pouring accuracy where small pours or a controlled pour stream is required.

Infographic

Infographic

Literature

Literature

Article

Article