Chargeminder® Systems

Chargeminder® Charge Recipe Monitoring Systems allow you to create, edit, store, and retrieve multiple charge “recipes”. This advanced system can be used for creating charge recipes and can also provide crane and magnet operators with visual feedback during the charge makeup process.

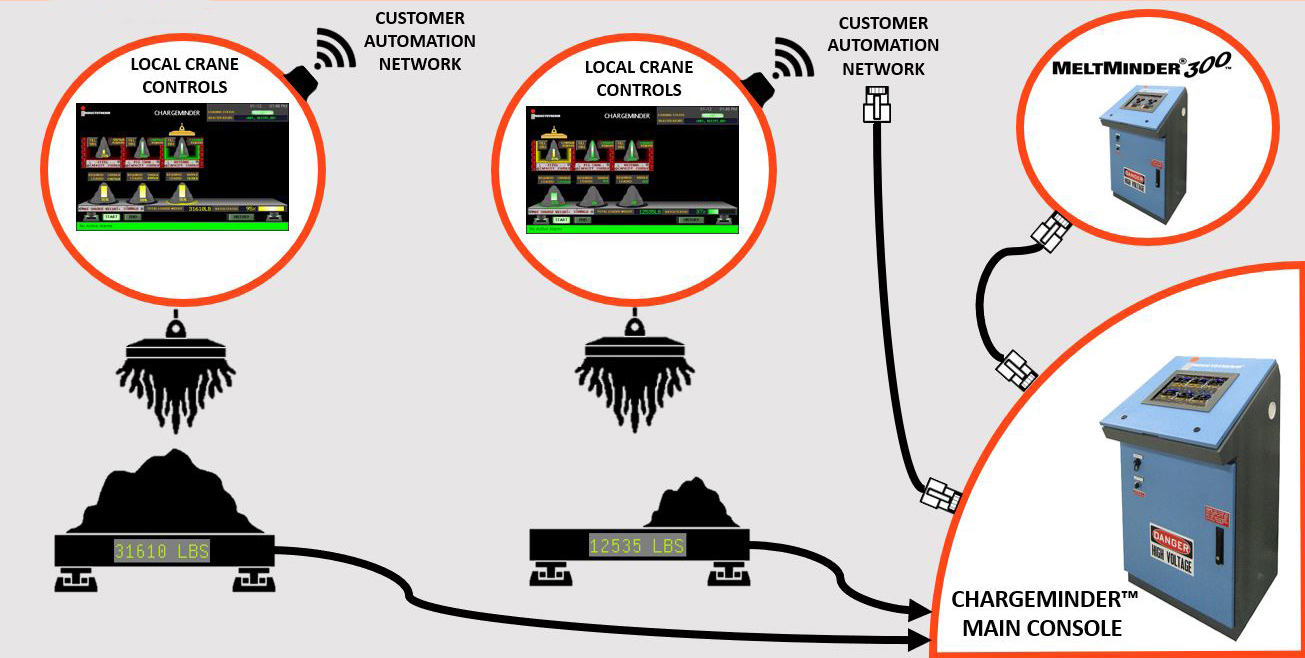

The Chargeminder® System brings together the customer’s local crane controls with the customer’s automation network to seamlessly deliver constant monitoring in real time. Whether you have one or more melt systems, Inductotherm’s Chargeminder® Charge Recipe and Monitoring System is easy to install. This system can help your charge makeup operators quickly and efficiently get the correct charge to the correct furnace for a more consistent melt.

The Chargeminder™ system is designed to simplify the process of loading scrap metal based on recipes. The first feature of the system is creating and editing a library of charge recipes to meet different melt requirements. A melt supervisor can pick a recipe from the library or create new recipes, as needed. Once a recipe has been chosen for loading, the system will provide clear visual feedback to help guide the crane and magnet operators through the batch-making process. This is the second feature of the system. Another advantage of the system is that it has no bulky, hard-to-install components. It is designed to interface easily with and enhance common scrap-weighing equipment.

SYSTEM PRE-REQUISITES

Most induction melt systems can be easily upgraded. All you need is a charge conveyor, weigh frame, loadcell conditioning module with analog input. Most melt shops today have some, if not all, of this equipment already included and often upgrades can be done with little to no downtime.

SYSTEM TOPOLOGY